10% off your first order

Register and receive a 10% discount code by e-mail to use on your first order.

We do our utmost to design collections that are technical, aesthetic and eco-responsible.

We want to offer you the best so that your products will last over time.

The choice of material quality and the type and position of seams

are a priority to ensure you feel good while practicing your sport.

Designed for long or intense effort, our fabrics will provide you with optimum comfort for hours on end.

Moov360 works in collaboration with textile designers to study the cuts, design and style of collections as the seasons progress.

The choice of our fabrics is crucial to the entire production chain, and we are committed to using only recycled or natural materials.

This complicates work on the overall look and style, but is a key element of our brand.

Once the product has been designed, we start creating the 1st prototypes in our Italian factory.

The products are then tested with sportsmen and women and athletes to validate the comfort, fit and technicality of our sporting goods.

This stage can take up to 4 months to validate our products correctly.

Patterns and technical data sheets are then produced with our partner factories.

The design of the collections can then begin in our workshops in Italy, where the final fabrics chosen are carefully assembled (flat seams, logos, bonding, etc.).

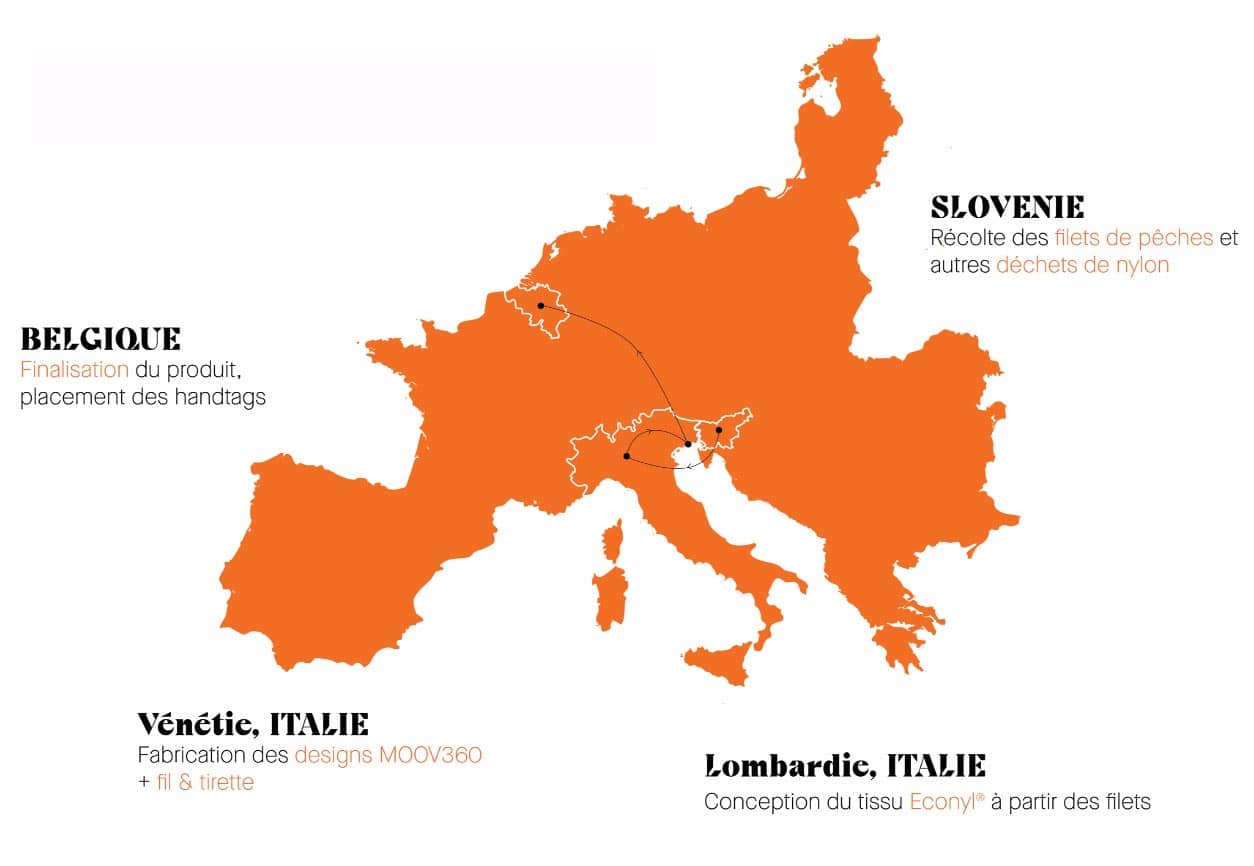

ECONYL® yarn is a 100% recycled nylon fiber, made from plastic waste that is first sorted and washed before being ground, melted and then spun again. The resulting Econyl ® is used to manufacture new garments, which are themselves 100% recyclable.

The production of Econyl ® helps to protect marine ecosystems by recovering scraps of fabric, carpet lint and abandoned fishing nets from the oceans, where they would have taken decades to degrade and are a mortal danger to animals.

Recovery of fishing nets

Transformation into granules

Wire design

Moov360 works with Aquafil, parent company of ECONYL®, to produce its eco-friendly garments.

For 50 years, Aquafil has been a producer of yarns for carpets and garments, and a leading player in the production of Polyamide 6 and recycled yarns.

The use of ECONYL® fabric reduces the product’s carbon footprint by almost 90% compared to a product made with petroleum-based materials.

With a distance of 400km between the recovery of recycled waste and the manufacture of our collections, Moov360 aims to minimize its impact at every level of the production chain.

Healthy Seas

is an organization that cleans the oceans of marine litter (particularly fishing nets), but also educates fishermen and the public about water pollution.

Moov360

is committed to cleaning up our oceans and protecting marine life by donating 1% of its sales to Healthy Seas.

As with our entire range, our products containelastane which provides softness and flexibility important attributes for sportswear.

However, it’s important to stress that elastane remains a synthetic material that is not yet recyclable and contains microplastics. That’s why we’re constantly on the lookout for new, more eco-friendly materials to replace the elastane in our clothes.

In order to reduce its impact, we are already offering the possibility of purchasing a

GUPPYFRIEND

bag with your garments, which prevents the release of microplastics into the water during machine washing.

Subscribe to our newsletter

Keep an eye on our news, exclusives and sports tips.

By submitting this form, I accept that the information collected

be used to send me the Newsletter.

Register and receive a 10% discount code by e-mail to use on your first order.